Categories

All

Agriculture

Airbag Reset

Alfa Romeo

Aston-martin

Audi

Auto Accident

Auto-insurance

Bentley

BMW

BMW Courses

BMW HDD

Bmw Headunit

Byd

Cadillac

Chery

Chevrolet

Chrysler

Citroen

Cluster

Commercial Ads

Coolant Systems

CUPRA

Dealer Package

Dodge

DTC Fault Codes

ECU Courses

ECU Tester

Electric Hybrid

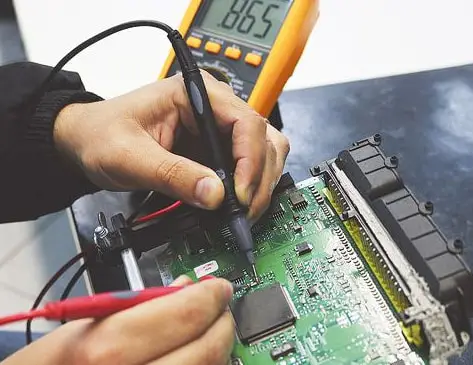

Electronic Repair

Electronics & Parts

Emission Env.

Engines Diesel

Engine Sensors

Engines Petrol

Engine Tuning

Exhaust Systems

FADOS Fault Locator

Ferrari Maserati

Fiat

File Service Portal

FORD

Fuel

GAC

GMC

Haval

Headlights

Headunits

IC Testers

IGBT Mosfet Tester

Industrial Auto

Isuzu

Iveco

Jac

Jaguar

Jeep

Key Programmer

Kia Hyundai

Lamborghini

Landrange Rover

Lincoln

Lotus

Mahindra

Mazda

Mclaren

Mercedes

MG

Mit Canter Fuso

Mitsubishi

New Holland

Nissan

Opel

Pagani

Peugeot

Pops Bangs

Porsche

Programmers

Renault

Repair Manuals

Rivian

Seat

Skoda

Ssangyong

Suspension

Tesla

Toyota

Transmission

Trucks DAF

Trucks Engine Tuning

Trucks MAN

Trucks Mercedes

Trucks Scania

Truck Volvo

Tuning Courses

Turbocharger

Vauxhall

Volvo

Vw Volkswagen